Professional Project

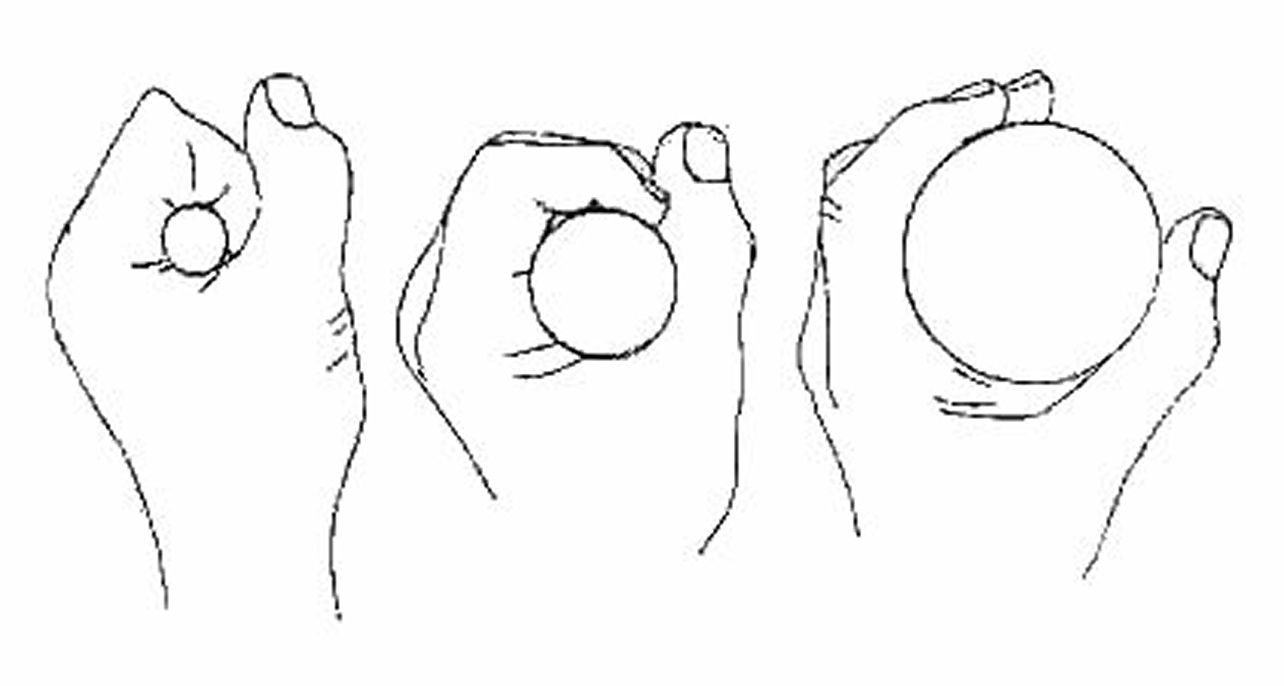

The inner grip diameter was redefined using 5th–50th percentile Indian female hand anthropometry to ensure a comfortable grip for the primary user group. A diameter of ~30–32 mm was selected to balance grip strength, comfort, and safety during lifting

Most pressure cookers in the market feature oversized handle grip diameters (often exceeding 45 mm), driven largely by legacy design practices rather than user-specific ergonomics.

COOKERDSH

COOKER HANDLE CONCEPTS

COOKERDSH

C1

C2

C3

C1 - This concept rethinks the conventional top–bottom handle split by redistributing volume between the two parts, creating a more dynamic silhouette. Subtle stainless-steel embellishments on both sides add perceived value while maintaining functional familiarity.

C2 - This concept explores a more fluid, blended form between the handle, unlike the typical straight line. The focus was on cleaner cuts and seamless form transitions, giving the handle a sculpted, premium feel yet visually lighter.

C3 - This concept aligns closely with market-familiar minimal designs while adding subtle curvature on both sides of the handle to better follow the natural grip of the hand. Material bulk is reduced in the lower handle to optimize weight and efficiency without compromising strength.

COOKERDSH

COOKERDSH

MIXER GRINDER HANDLE CONCEPTS

M1

M2

M3

M1 - This concept explores a highly organic form language inspired by the bird (pigeon) and the natural curvature of the human grip.`

M2 - Positioned between minimal and organic, this concept maintains a clean front profile while introducing subtle personality from the side. Inspired by natural ridges of birds, the detailing enhances grip at key contact points,

M3 - This concept distills the handle down to its essentials, guided by typical user thumb placement while interacting with the product. A subtle scooped surface provides ergonomic support while keeping the overall geometry minimal and unobtrusive.

TECHNICAL 3D MODEL

COOKERDSH

COOKERDSH

The handle was modeled in PTC Creo and refined through multiple client discussions to align with manufacturing and cost requirements. Material was strategically reduced to optimize tooling and production cost, and all user touch-points were carefully rounded to enhance comfort and usability.

The fluidic protrusion emerged as a recurring feature that is subtle yet recognizable. It was ergonomic in function and expressive in form

“This is the most comfortable pressure cooker I’ve ever used, and no, it’s not because you designed it.”

— My mom

Beyond prototyping and testing, this pressure cooker has been part of my daily cooking routine for the past four years

Key Learning

User-specific anthropometric data can meaningfully challenge and improve industry-standard dimensions.

Iterative detailing is where design intent translates into real product value.

Value Addition

Improved user comfort through ergonomically optimized grip geometry.

Material-efficient handle design contributing to reduced manufacturing cost.